D100

60% of global transportation emissions are from diesel engines.

Electrifying heavy vehicles faces significant challenges as the required battery size is prohibitive and EV recharging or hydrogen refuelling infrastructure is not extensive enough, particularly in remote locations. Changing over a fleet of heavy vehicles to EV or hydrogen fuel cells is very, very expensive. Our D100 unit is easily retrofitted to any existing diesel engine with fuel and CO2 emission savings in the range of 8 to 15%. With no-upfront capital investment required nor any retuning of the diesel engine the units benefits materially outweigh the monthly fee.

The D100 is a here and now product that assists in reducing emissions immediately.

This compact unit lets us introduce small amounts of Hydrogen, or more accurately HHO, into the air intake of a standard diesel engine. The HHO is generated on-demand, so no storage and no high pressures. The amount we introduce is minor and therefore no adjustment to the engine is required. The main mechanism at work here is that HHO allows the engine to burn diesel more efficiently and keep the combustion more complete.

DEPLOYABLE TODAY

The D100 is specifically targeted at trucks, buses and ferries.

It is commercially available now.

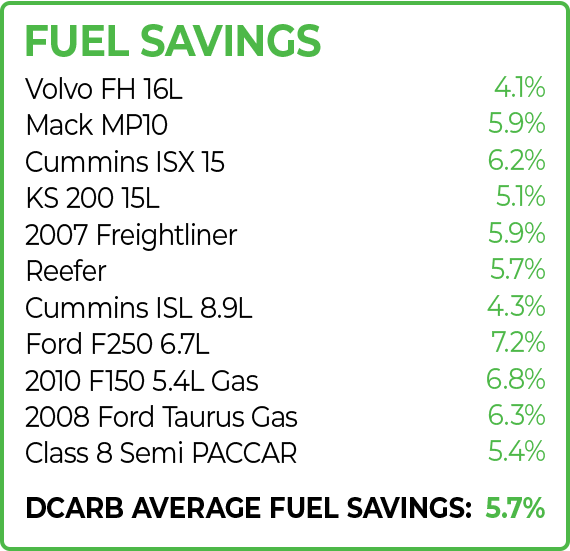

The real-world benefits are immediate fuels savings of 8 to 15%, which means a reduction of CO2 emissions by a similar amount. We also see a large reduction in particulates from the diesel engine.

Deploying a D100 unit saves money and helps saves the environment. A Win, Win!

Other benefits include better driving experience with higher torque and reduced engine maintenance and the potential to obtain carbon or tax credits for the reduction in CO2 emissions. We provide the D100 unit as a service or subscription model. We expect our monthly fee to be covered by some of the fuel savings we provide our customers. So, no Capex required.

The D100 unit can be retrofitted to almost any existing diesel asset to provide a Hydrogen co-fueling solution that will deliver immediate benefits:

Reduced Particulate Emissions Up

Improved Oil Quality Over Service Life

Reduced Fuel Consumption 8-15%

Greater Torque Eficiency 4-6%

Reduced CO2 emissions Up To 8-15%

Our system does not store Hydrogen, instead, it stores water, and using our patented technology it converts the water to hydrogen and O oxygen on demand. Water is a significantly safer and easier way to store hydrogen than in highly pressurized tanks and is much more convenient to refill when depleted.

As an additional benefit from using water, we supplement the combustion process with additional oxygen thus further helping the process burn more completely.

DCARB are an impact based company with sustainability at our core.

Our purpose is to help decarbonize our planet – NOW.

We achieve this through creating strongly aligned, long term partnerships with our clients and completely decarbonising their diesel engine fleets over the coming years through ground-breaking hydrogen solutions.

Available today is our D100 technology at ZERO up front cost on a no risk, no lock in period subscription basis, which will yield immediate carbon and cost savings of up to 15%.

Bring Back Performance Power Economy & Track It All...

Up to 15% reduction in fuel Consumption

Particulates up to 75%

CO2 up to 15%

NOX up to 30%

Torque Increase 4%

Oil Soot levels reduced from 8% to 1%

Total Package Hardware and Software solution with full transparency and visibility

IT'S THE "HYDRO" IN HYDROCARBON (DIESEL)

Diesel is a complex Hydrocarbon. During the combustion process, all the Hydrogen is burned off whereas the carbon is only partially burned. This is the black ‘soot’ layer that can be found throughout the engine.

THE CARBON BUILDS UP INSIDE THE ENGINE

The Carbon causes significant engine performance problems by:

Building up in vital areas and restricting the airflow.

Building up on nozzle tips affecting diesel atomization and therefore combustion.

Building up within after treatment systems creating exhaust back pressure impacting efficiency and power.

Building up on turbo charger affecting turbo charger efficiency and increasing turbo lag.

HOW DCARB WORKS:

By adding a small amount of text of hydrogen during the combustion process the fuel is more completely burned. In addition, the hydrogen bonds with the carbon that has built-up in the engine frame. This forms a low-energy hydrogen carbon that leaves the engine as CO2 gas – removing these deposits.